FEATURES & SPECIFICATIONS

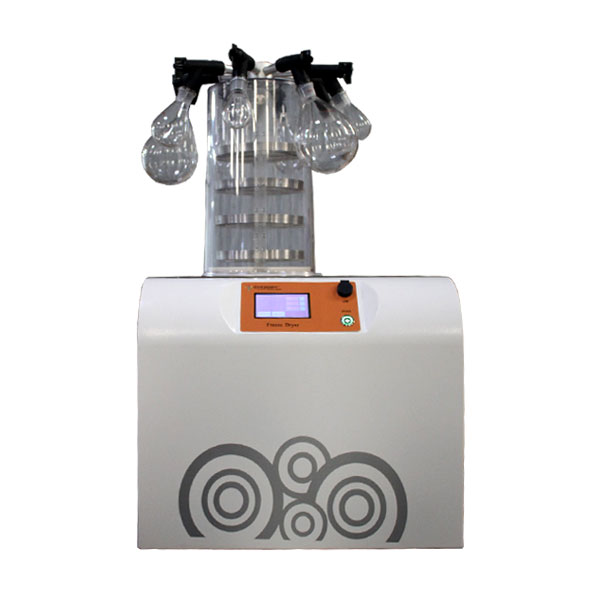

DESCRIPTION:

The vacuum freeze-drying technology, which is also called sublimation drying, is a technical method that freezes the sample in advance, and then sublimation its moisture in the vacuum state. Goods are easier for longterm preservation after freeze drying processing. So, the freeze- drying technology Is widely used in medicine, food, chemistry industry and biological products etc.

FEATURES:

- SECOP compressor, helps to maintain rapid refrigeration by Lowering the temperature.

- LCD touch screen control system, with simple operation.

- The control system automatically stores data, and data can be viewed in form of the curve. Data also can be output by USB port.

- The drying chamber uses transparent acrylic drum. user can clearly view sample state and observe the whole freeze-drying process

- Performance of machine is stable,easy to operate and low noise.

- Automatic start- up feature.

- Hot gas defrosts for fast turn around time,eliminating waiting time between freeze drying cycles.

- Vacuum level control to assist in speeding up the drying process.

- System have vacuum brake solenoid(VBS) valve for extra protection against Vacuum pump oil being drawn back into product chamber in the event of power failure or Accident shut down. Vacuum pump connected with host by international standard KF quick joint.

SPECIFICATIONS:

| Specifications | Parameters |

|---|---|

| Model | IG-LZ10P |

| Minimumcondens er temperature | -55ºC(no-load)/-80ºC |

| Finalvacuum | <10Pa |

| Traysize | Dia.200mm,4pcs |

| Liquidbulkcapacity | 1200ml(10mm thickness) |

| Manifoldports | 8 |

| Round bottom flask | 500ml,8pcs |

| Working Temperature | 10ºC-25ºC |

| Relative Humidity | ≤70% |

| Power supply | AC220V±10%,50/60Hz |

| Compressor Horsepower | 2 x 1/2HP |

| Condensor Capacity | 05 kg with pre- freezing |

| Optional Accessories | I. Nitrogen valve II. Communication interface (upgradation is available) |

Reviews

There are no reviews yet.